Manufacturer and Exporter of : Electronic Universal Testing Machine - Electronic UTM

Features - Universal Testing Machine

- Open type cross head

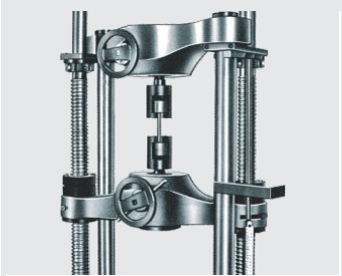

- Hydraulic wedge action grips with separate power pack

- Long test stroke and test space

- VFD based Servo control incorporating of control modes - Standard manual control, Load rate control, Elongation rate control, Load hold mode, Auto start & Stress rate control.

- Loading accuracy as high as ± 1% Straining at variable speeds to suit a wide range of materials.

- Printer & PC graphs enable study the behaviour of the material.

- Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen.

- Simplicity in reading because of digital readouts.

- Wide range of standard and special accessories. Including load stabilizer.

- Easy change from plain to threaded and screwed specimens.

- Large effective clearance between columns enables testing of standards specimens as well as structures.

- Simple controls for ease of operation.

- Robust straining frame of an extremely rigid construction.

- Safe operation ensured by means of safety devices.

- Fully enclosed and protected pressure transducer.

- USB control for data to computer for analysis / storage evaluation etc.

- Manual control & release valve operation.

- Manual control & release valve operation. ● Load Capacity : 100 kN, 200 kN, 400 kN, 600 kN, 1000 kN, 1200 kN, 1500 kN & 2000 kN.

Electronic Control Panel Series UTES-2020 :

PLC based panel with following features -

- Industrial grade HMI for display.

- Data entry with Touch screen HMI of test parameters including rupture %, preload %, safe load etc.

- Panel communication with PC through MODBUS serial protocol.

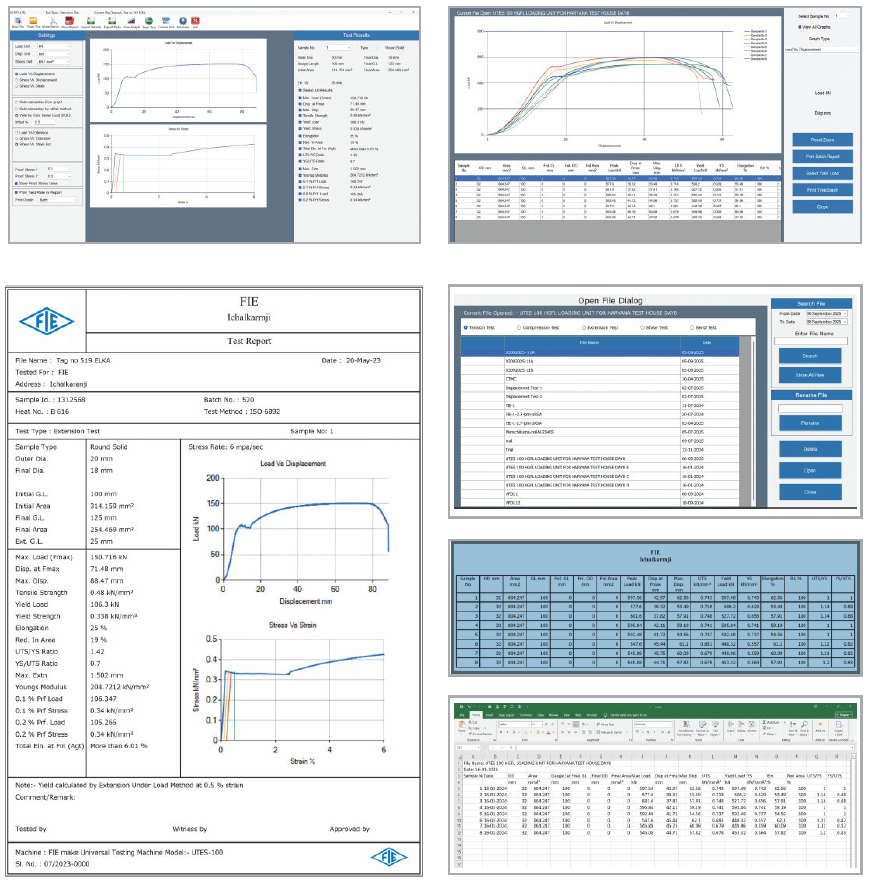

Windows based software feature

- Online graph on PC, Data analysis, Statistics, Point tracing, superimposing graphs to compare with standard, zooming graph etc.

- Report customization as per custom requirements.

- Video Extensometer compatible.

- R & N value extensometer compatible.

- Proof stress calculation from 0.1% to 1%.

- Integration of custom sample.

- Single point software calibration.

- Facility to export data to PDF, EXCEL & CSV formats.

- Unit selection for Real time Graph.

- Unlimited Test in single batch file.

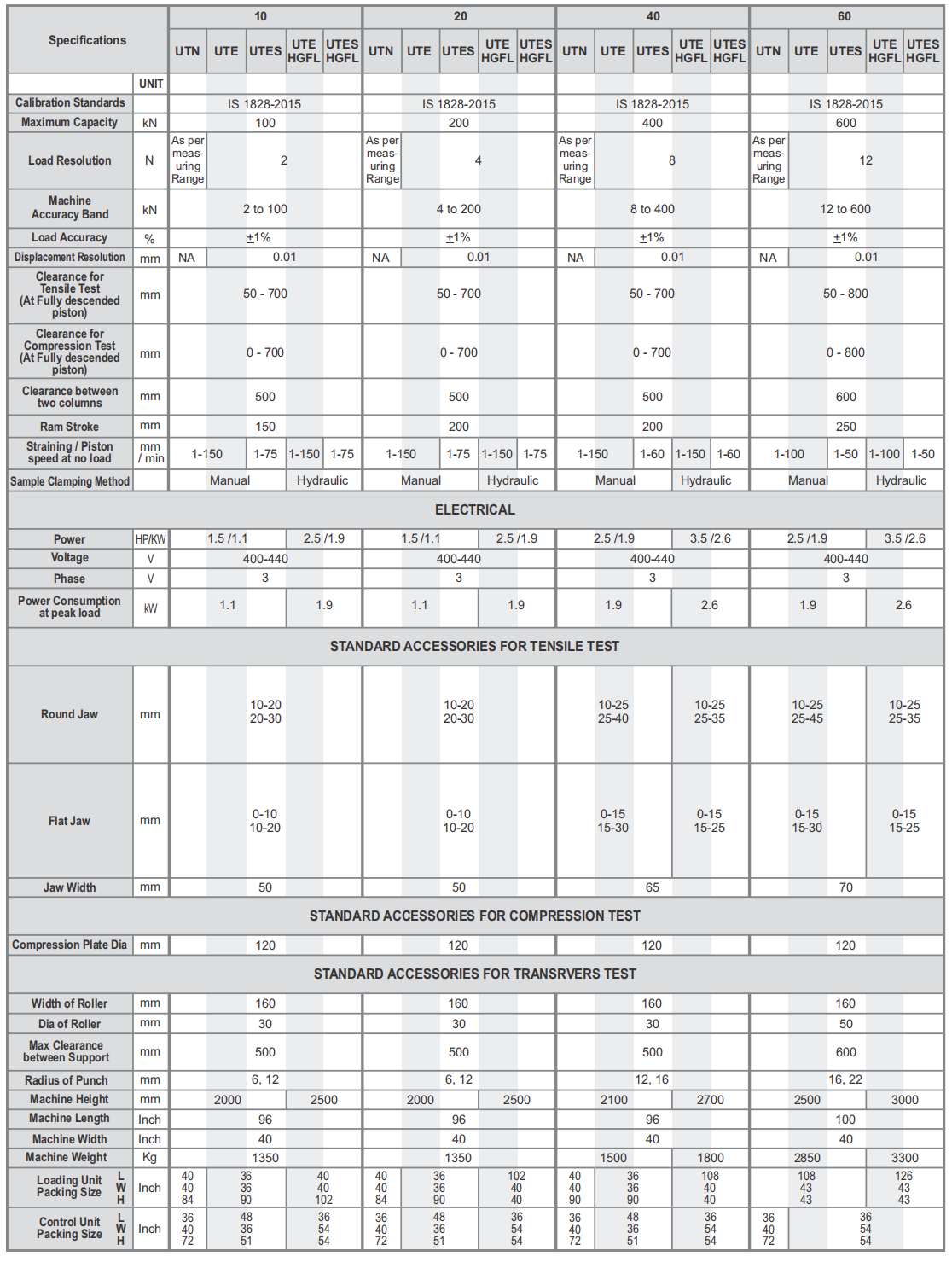

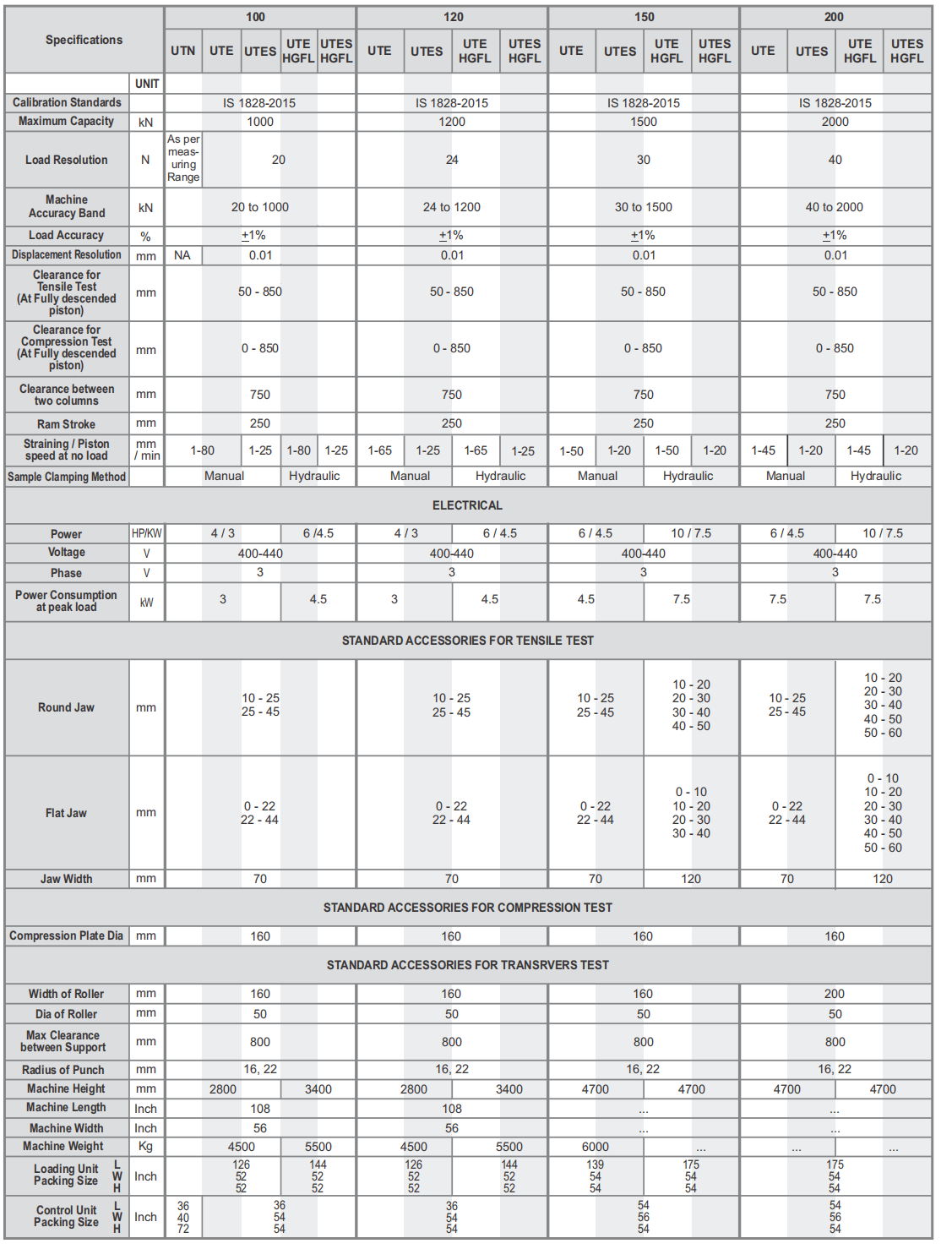

Technical Specifications - Universal Testing Machine

Accessories and Consumables - Universal Testing Machine

Analogue Cum Digital UTM machine Available for UTN series models

Panel with Touch screen Industrial PC Applicable for all models

Strand wire grips

Applicable for HGFL Models

Electronic extensometer Applicable for all models

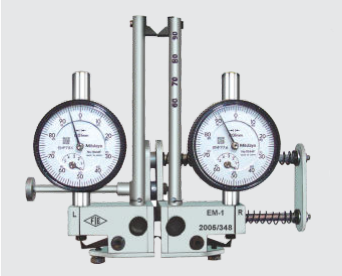

Mechanical Extensometer Applicable for all models

Attachment for Shouldered & Threaded Specimens M6 to M28 Applicable for all models

Brinell Hardness Test attachment Applicable for all models

Adjustable Gauge length Electronic Extensometer

Video Extensometer Applicable for all models

Shear Test attachment Applicable for all models

180° Bend Test attachment & mandrels Applicable for all models

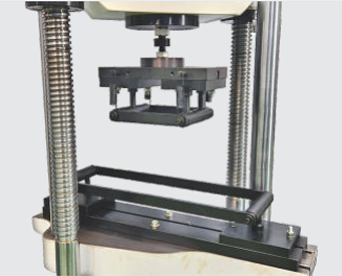

Flexural Test attachment Applicable for all models