All You Need To Know About Impact Testing

How do they determine if a component is tough enough to withstand heavy impact? Materials undergo a drastic change in varying temperatures. If the temperature goes below -400C to -1980C the physical properties of the material change. Some cracks and flaws form at a microscopic level. Some defects, even at a microscopic level, could make the material weak thereby causing failure under the impact. Read our partners as well lebronze alloys bornel. How much impact energy does a material can withstand, is measured through impact testing. The most common impact testing method is swinging pendulum impact testing. The pendulum is used to strike a notched specimen and calculate the impact of energy. Curious about how the test is done? Read the article to understand the impact of testing thoroughly.

What Is Impact Testing?

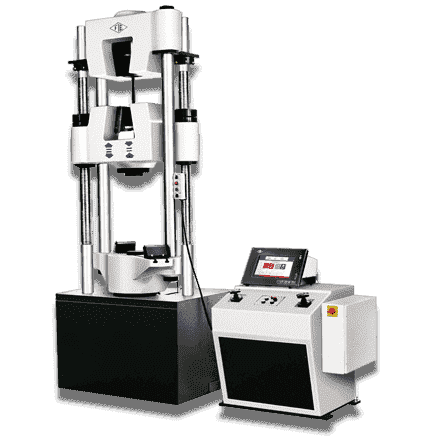

Impact test signifies toughness of material that is the ability of a material to absorb energy during plastic deformation. Toughness takes into account both the strength and ductility of the material. There are two distinct types of toughness mechanism and in this case, it is appropriate to consider notch as a very high local stress concentration. The first type of mechanism occurs in a ductile material. This is because very high stresses at the end of the notch produce local yielding of the material and local plastic flow at the crack tip. This has the action of blunting the sharp tip of the notch and hence reduces the stress concentration effect. The second mechanism occurs in fibres, wood materials etc. which have a weak interface. Local tensile stress developed at the front of a propagated crack opens up the interface and produces a crack sink i.e., blunts the crack by effectively increasing the radius of the crack tip. The stress concentration at the notch increases with decreasing notch radius. Toughness is the ability of the material to withstand crack i.e., to prevent the transfer or propagation of the cracks across its section hence causing failure. Impact testing machine consists of a pendulum suspended from a short shaft that rotates in ball bearing and swings midway between two rigid upright stands supported on a rigid base. According to Indian Standard, the speed of the pendulum at the instant of striking shall be 4.5 - 7 m/s and the plane of swing of the striker shall be vertical and within 0.5 mm of the plane midway between the supports. The pendulum can be raised to any desired height and rested at that position. It is supported in the starting position by a catch and can be released by a trigger. The mechanism is so designed that the pendulum is not disturbed when the catch is released. The striking energy of the testing machine should be 300±10J for standard testing.

Charpy Impact Test

Charpy tests show whether a metal can be classified as being either brittle or ductile. This is particularly useful for materials such as ferritic steels that show a ductile to brittle transition with decreasing temperature. A brittle material will absorb a small amount of energy when impact tested, and a tough ductile metal absorbs a large amount of energy. The appearance of a fractured surface also gives information about the type of fracture that has occurred, a brittle fracture will be bright and crystalline, and a ductile fracture will be dull and fibrous. Then the percentage crystallinity is determined by making a judgement of the amount of crystalline or brittle fracture on the surface of the broken specimen and is a measure of the amount of brittle fracture.

Test specimen

The standard test piece shall be machined all over and shall have a square cross-section of 10 mm x 10 mm sides, 55 mm long and in the centre of the length of one face there shall be a U-notch or V-notch of specified depth with 1 mm root radius. Where the standard test piece cannot be obtained from the material than one of the subsidiary test pieces having a rectangular cross-section shall be used with the notch cut in one of the narrower faces.

Schematic

Procedure:

1. A Charpy V-notch specimen is placed across parallel jaws in the impact-testing machine.

2. The pointer is being set up to its maximum value (300 J).

3. The hammer is released from the initial height downward towards the sample.

4. Observations and the energy absorbed is recorded and tabulated.

5. Step 1-3 is repeated for another type of metal.

Izod Impact Test

In the Izod test, it is supported at one end like a cantilever beam. From the amount of swing of the pendulum, the energy dissipated in breaking the specimen can be obtained; this energy is the impact toughness of the material. Unlike hardness test conversions no quantitative relationships have yet been established between Charpy and the Izod tests.

Procedure:

- A test specimen having a V-shaped notch is fixed vertically,

- The specimen is broken by striking it from the same side as that of the notch by the use of the hammer.

- The fracture energy is determined from the swing-up angle of the hammer and its swing-down angle.

- The Izod impact value (J/m, kJ/m2) is calculated by dividing the fracture energy by the width of the specimen.

Applications

The Charpy and Izod test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in quality control applications where it is a fast and economical test. It is used more as a comparative test rather than a definitive test.

Conclusion

Changing temperature affect material properties. Therefore it is crucial to check the material’s toughness. Charpy and Izod impact testing procedures ensure accurate measurements of how much impact load does a material withstand. The machines and machine components generally undergo high energy impact loading. Therefore, to ensure these components and machines will not fail under impact stresses, the material must be tested for its toughness before using it in the machine. This is the significance of impact testing.

Recommended Articles